This guitar is YAMAHA FG-110 bought at a certain auction.

A neck is an order curve and there is more than 5 mm of height of 1 handle by 12 frets.

An adjustment is slightly necessary, isn’t it?

、、、 which will turn a truss rod right away

Oh, 、、、、 it’ll be much and I don’t go around any more.

But it’s OK.

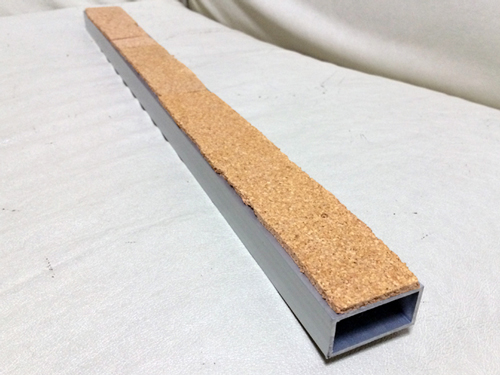

Something to prepare

- Square lumber of aluminum(20mm × 40mm × 500mm)

- Cork seat

- 3 clamps

- 200W light bulb and the LED bad

A cork seat is stuck on a one side of aluminum material.

A truss rod of a guitar is reduced loosely.

I’ll place a guitar on the table and go out of only the neck part in the air.

And the aluminum material a short while ago is fixed by a clamp so that cork may be cross with a neck.

200W working light is installed just below the neck.

A working light is lit and it’s left for about 4 hours.

It becomes quite hot, so being not a fire, in the environment, a thing, accord.

An amateur-like neck heater.

It can be corrected really, please do you overcome?

That’s made.

After I spend time and cool after heating it up.

When I’ll turn a truss rod.

It started to turn around to the location into which I stepped more than last time.

Look, appearance straightness!

When I strung, even a handle of 3.5 mm of 2.8mm and 6 handles hung on 12 frets for the handle amount.

As follows, of a notice certainly a charm please.

- This way doesn’t say to any neck order curves that it’s effective.

- A neck has the individual difference by the material, so please heat it while seeing how things are.

- Heating by a light bulb becomes hot beyond expectation. Please be careful about a fire sufficiently.

- When consulting this way, all responsibility results in itself. The responsibility which is entirely about a result isn’t shouldered.

The individual who corrected was played.